Weaving as Cultural Practice: What time of the year is it?

The selfie of my loom

My loom is like a housewife’s ill-used treadmill. It sits behind me in my office/studio beckoning me to ‘work’, to weave something, anything! Instead, at this point in my life I really need to read stuff, write things. My work table doesn’t hold fabric, waiting to be made into a suit. No. It holds collated readings for the grant proposal. Readings for probes. More readings for the paper I must write for the end of the term. The things is though, I’d rather do anything but write. And so, like a good academic, I have perfected the act of procrastination. Oh the ways that I can procrastinate, even though I know that if I would just sit here and write, there would be time left in the day to create. By the way, this is my loom’s first ever ‘selfie’, and the second ever ‘selfie’ of myself. I’m not usually one for modern technology.

For this probe, I am going to talk about weaving. This had been my plan since first reading the abstracts for the readings for this week. I weave to develop a better understanding of how people in the 18thC lived. I weave to firmly grasp how expensive clothing is, so different from what we see today. Yesterday I went out and spent 200$ and bought two pair of jeans, four T-shirts and four packages of underwear. Two Hundred dollars; that was all it cost for all those clothes. That is not the real and true cost of those items of clothing. In fact, if we were to harvest the fibres, process them, spin them, weave or knit the cloth, then make the garments, we would have a better understanding of the true cost of the clothes that we wear. And we would be outraged. But, back to weaving.

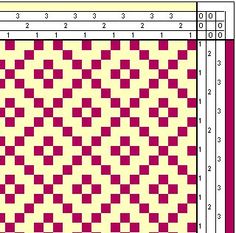

This is a weaving pattern. The main body of the pattern gives you a diagram of how the weave structure will look as you are weaving. The pattern in the cloth. There are many different varieties of weave structures that will give you different patterns in the cloth, and are used for different reasons. The jeans we wear are a twill weave. Twill stretches a bit and so makes our jeans more comfortable to wear, even if they don’t also have a stretchable fibre in them. Dish cloths tend to be woven in a variation of the twill that produces a waffle-like effect in the cloth. This allows for better containment of soap, and more scrubability. Dress shirts are woven with a plain weave structure. This makes ironing them easier and allows for a crisper finish.

The top bar of the pattern tells you how to thread the loom to achieve the pattern. The top right hand corner tells you how to tie-up the foot pedals to the loom. The bar that runs down the right hand side of the pattern tells you how to weave, giving you which pedals to press down with each step. This text allows weavers of many generations to understand and recreate cloth that may have been first woven hundreds of years ago. The structure of a weaving pattern has not changed in a very long time.

My loom is called a ‘colonial box loom’. It is a modern loom based on the style of looms that would have been created and used in the 18th century. My loom came to me in a very interesting way. This may seem like a bit of a side-bar, but is relevant to the story. Two years ago, I was able to spend a summer with the Nova Scotia Centre for Craft and Design. During that summer residency, I had full access to their weaving studio. My project was to recreate linen textiles from the 18th century. I had never woven with linen before, and there were some things I wanted to create for our re-enacting kit. Among these projects were dish cloths and towels, chair strapping, a tablecloth, and a length of shirt cloth. The shirt cloth was to be the major project, with the others being made up as time allowed. The shirt cloth yardage was supposed to be about 15 metres long, enough for several shirts and some aprons. Each of these textiles were based on historical weave patterns from a book written in the late 18th century, and the check pattern for the shirt cloth was based on a sample in the MET museum in Boston.

I began on July 1st. It took a week to wind off the threads for the warp of the shirt. The warp threads run the length of the cloth, and are what is threaded through the loom. As a weaver winds the warp threads on the warping mill, he/she counts off the pattern of the weave structure. I had to first determine how wide I wanted the cloth to be, and then how many threads I wanted to use, and in what order, colour-wise. This idea was then counted off while I wound the warp so that I would have a consistent pattern across the cloth, and would have enough threads to make the desired width.

This shirt warp took over a month to actually wind on to the back beam of the loom, ready to weave. The warp was wide, 30 inches. Normally it takes two of us to get a warp on to the loom so that I can thread it. This warp took three of us. I had to wait for pairs of friends to be willing and able to come into the studio with me. (In the meantime, I continued on with some of the other projects that I had on the go.) Also, the linen was very hairy thread, and liked to catch itself on the other threads, making large snarls. To ‘condition’ the threads to ease in this problem, I starched the threads once I took them off the warping mill. I then continuously sprayed the threads with even more starch as we wound the warp on the loom. Little did I know that the threads drying out would be a major issue (problem #1), and that my starching may have caused yet another issue (problem #2).

We finally got the warp on the loom and I began to thread. This took me two solid days of work. The warp was 30 inches wide and there were roughly 20 threads per inch. Roughly 600 threads to thread into the heddle eyes. And then threading 600 threads through the reeds. I really do enjoy this part of the weaving process. I put a Latin mass on my iPod and completely get into the zone of hanging in my loom, threading things. I really do hang inside the loom. The front bar comes off, and I get a chair inside as closely as I can to the heddles, and then I hang my arms over the beater bar and thread. It is tiring though, and hard on the body.

When I finally got everything ready to go, I decided to start fresh the next morning.

I usually start working very early in the morning, even when working in a studio outside my home. During this residency, I would start about 7am. The centre itself would open about 830am, with the public starting to come in to visit about 9am.

And so I go into the studio, get settled in for the day, sit down and begin to weave. I start with a really heavy thread. This is done to check the tension, and also to allow for a nice strong start to the weave. I may have thrown about five weft threads when I noticed that my tension was getting worse, not better. In fact, it was reaching catastrophic failure. WTH? I got up and then I noticed the back of the loom, where 15 metres of threads were at one time all nicely wound on the back beam. The threads that had been so lovely the night before had become a snarled mess. They slid off the sides of the coil of threads (problem #3), and were just a mess of thread on the back of the loom.

And here is where I was really glad that I was alone in the studio. The air turned blue as I cursed that warp in three languages and threw an epic temper tantrum. EPIC, I tell you, with tears and everything. I was still having a good cry, pulling the warp back off the back of the loom when a tourist walked in and said hello. He took one look at me and understood what was going on. He told me that his wife was a weaver, and that when she had this happen to her, he would disappear off to the pub until she called and told him it was safe for him to return. My first angel walked into my residency. This lady told me what was happening, told me it could be fixed, and then spent a good amount of time with me helping to get the warp off the loom without me cutting it to shreds. She told me how to fix problem #3. That weekend, my husband Pierre, friend Garth, and I got the warp back on the loom. I could finally weave.

This was the first of August. I had a little over a month left to go on my residency and far too much to accomplish. I set to weaving. This shirt warp proved to be difficult the entire time. I had to continually starch the warp as I wove. I got into a routine of spraying the warp with starch, while I waited for it to dry just enough, I would knit, then when I hit the sweet spot of dampness, I would weave like a fiend until the warp got too dry. Spray. Knit. Weave. Repeat. During the month of August, I wove 6 metres of shirt warp, knit a pair of stockings and a pair of 18th century ladies mitts. My other weaving projects I finished up in July, thank goodness.

My second angel was also a weaver who came into the studio one morning and sat with me for a good part of the day, talking about historical textiles and clothing. She was on her was to the UK to take part in an experimental archaeology conference, meeting a friend who had just done what I was doing. Her friend was recreating Norse textiles, a process far more difficult than what I was undertaking, but close. This new weaver angle asked why I was working at the centre. Did I not have a studio at home? I told her that no, I did not have a loom of my own. She told me that once she was back in Canada she would email me. She had some things she’d like to discuss with me, one of which was a loom.

The Labour Day weekend there was an encampment at the Halifax Citadel. I spent the entire weekend at the encampment, in historic dress, constructing historical clothing. That weekend I got most of one shirt made. I finished it up on the Tuesday at home, and Tuesday evening, with great hesitation, I put the shirt in the wash. With so much starch, the shirt felt as if it were made of cardboard. I had to mount my portion of the final exhibit on Wednesday for the opening on Thursday night. I figured at that point, if the linen completely self-destructed in the wash, I’d have a fun story to tell during the opening. The shirt survived the wash though, and the exhibit was a success. It was the very first time any of my work had been placed in a gallery exhibit. I was excited and happy with my work.

At this point, I realize that this has become a wordy post. There are things that I needed to tell you though, so that the problems could be discussed fully. I’ll start by telling you that at the beginning, I wove both dish towelling and dish cloths. They were woven using the same warp, the same threading of the loom. I changed the weave structure of the cloth by changing how I tied-up my pedals underneath the loom, and the steps I took to weave. So if looking at the pattern of the weave, the top bar was the same for both types of cloth. What changed was the top right hand corner, and the bar along the right hand side. This made the difference between a waffle pattern for the dish cloths, and a bird’s eye twill for the towelling. This project went perfectly from start to finish. My chair strapping also went perfectly. The tablecloth didn’t make it past winding the warp on the back of the loom because this is where things started to go wrong with my shirt warp. In all, I had four looms on the go that summer.

And so the shirt warp. Going back to problem #1, you may notice that the threads were drying out. This was due to the fact that I was working in an air conditioned space. A space where I could not turn the air conditioning off. Air conditioning works by drawing the moisture out of the air. It also drew the moisture out of my threads. Problem #2, my having to constantly starch the thread lead to there being far too much starch on the thread. This lead to the cardboard quality of the fabric, but also may have, most likely had, contributed to the looseness of the weave structure. No matter how much I beat the weft threads into the course before, I could not get the fabric to weave tightly enough. The resulting fabric has a characteristic of cheesecloth, only really heavy cheesecloth. Reducing the size of the weft threads might help negate this issue. I am planning to try with the remainder of the shirt warp, once I get back to weaving again.

Problem #3 came from how I was taught to wind a warp on to the back beam of a loom. I was taught to use paper between each course of winding, to separate the threads. The studio used cardboard, which was waffled in the middle. This waffling lead to the cardboard collapsing, which I had learned on another warp, and so with the shirt warp, I went back to paper. Because the warp was so long, and so wide, the paper could not handle the task of keeping the threads neat and tidy. My shirt warp slid off the edges of the paper. Angel #1 told me that I should be using sticks to separate the warp. That wood will not collapse, and will hold the threads properly. The studio was full of sticks, as you use pairs of them to keep threads separate in the back of the heddle harnesses.

Angel #2 returned from the UK and did email me. It turns out that she was a sheep farmer, and a weaver. When she bought her current farm, she found an older model, colonial box loom from LeClerc. She had several looms already, and would I like to have this loom? My family and I drove up to her farm, spending the afternoon with her before bringing my loom home to Halifax. While there I learned about the sheep she bred. How those heritage breed sheep were black when they were young, and then as they got older, they turned white. This would start me thinking about what I had learned about Norse clothing years before. I also learned that she has waste warps on her looms, that run from the back beam through the heddles and reeds, and that she ties her warp threads to these waste threads to making threading much faster. Since most of what she weaves is similar in threading, she just reused the waste threads over and over again. Each loom had a different threading.

That winter, Ross Farm museum had a flax production day. Garth and my family decided we needed to attend. We learned about how flax is grown, harvested and processed into fibres and then spun into linen thread. Garth and I both were able to spin for a bit, and I learned that I could get a far finer thread with my very limited background in spinning than I ever could buy.

This trip also got me thinking about the ‘when’ of how fibres are processed, and how this may influence textile production. When you really begin to think about the ‘when’ of things, it starts to make sense how the problems arose in my own production. Linen is harvested in the Fall, it is then laid out to basically rot in the sun and the rain, separating the fibres from the reed it grew as. These fibres are then spun in the early winter months, and fabric can be woven in the wettest period of our year in Nova Scotia, the late winter. Sheep are sheared in the spring, and the fibres are spun then and weaving this fibre may happen in the late spring, when the weather begins to dry up, but it is still not hot. Summer months are for sowing, caring for and harvesting crops. There is usually not enough time in the day to be spinning or weaving cloth, but there may be time to sew clothing. In fact, the summer months are my most favourite times to sew, as my hands stay nice and warm, making it easier to hold the needle.

The time of year, coupled with the problem of the air conditioning made for an uncomfortable summer of textile production for me. I knew how to weave. I knew how to reproduce the patterns from the historical text. Until I encountered the issues that I had with the shirt warp though, I did not fully grasp all of the concepts of historical textile production. The difference between the “knowing how’ and ‘knowing that’; skill and knowledge going their separate ways” (Kramer and Bredekamp, 2013, p. 26). In the Siegert article, the author tells us that ‘cultural techniques always have to take account of what they exclude” (Siegert, 2013, p. 62). There was a lot that was not taken into account with the historical text, the least of which was the assumption that I would have had a firm enough background in weaving to know that I should not be weaving in the hot or dry conditions. I am now a firm believer in the importance of practice based research, in that I would not have fully understood the research I had undertaken to that point if I had not taken into consideration the daily practices of farming and producing textiles myself. I will never again have air conditioning in my studio. I will be mindful of the tasks I complete and the time of year. In the future, I also hope to grow my own flax and produce my own threads to weave with, so that I may have a better understanding of how much clothing is ‘worth’. That first shirt project was meant to study the production of cloth into shirt, and then how long that shirt would last through wearing. I know now, that the shirt will not last as long as a more tightly woven cloth would. The looseness of the weave structure is already producing stress points that will contribute to the wearing out of the shirt. We will see if I can get a tighter weave structure out or future attempts with the remaining warp threads. I hope so.

Works Cited

Bredekamp, S. K. (2013). Culture, Technology, Cultural Techniques – Moving Beyond Text1. Theory Culture Society, 20-29.

Bronson, J. a. (1977). Early American Weaving and Dyeing: The Domestic Manufacturer’s Assistant and Family Directory in the Arts of Weaving and Dyeing. New York: Dover.

Dixon, A. (2007). The Handweaver’s Pattern Directory. Loveland CO: Interweave Press.

Siegert, B. (2013). Cultural Techniques: Or the End of the Intellectual Postwar Era in German Media Theory. Theory, Culture and Society, 48-65.

Sterne, J. (2003). Bourdieu, Technique and Technology. Cultural Studies, 367-389.